Sulphate resistant cement / for concreting at extremely high temperatures.

Specifically adapted for construction where groundwater and humid environment have a high sulphate content and for making a concrete at extremely high temperatures.

Sulphate resistant cement / for concreting at extremely high temperatures.

Specifically adapted for construction where groundwater and humid environment have a high sulphate content and for making a concrete at extremely high temperatures.

Sulphate resistant cement with low heat of hydration, with a blast-furnace slag content of 66%-80%, and 20%-34% of clinker, including a natural gypsum as regulating binding agent. The certificate of conformity to specifications: HRN EN197-1 i HRN EN197-2, BAS EN 197-1, BAS EN 197-2.

| Physical & mechanical and chemical characteristics | SULFALUK CEM III/B 32,5 N SR-LH | Requirements under BAS EN 197-1 |

|---|---|---|

| Stability of the volume by La Chatelier (mm) | 0,1 | ≤10 |

| Setting time (min) | 200 | ≥75 |

| Compressive strength on 7 days (Mpa) | 20,8 | ≥16 |

| Compressive strength on 28 days (Mpa) | 41,0 | ≥32,5≤52,5 |

| Heat of hydration (J/gr) | 180 | ≤270 |

| Sulphate content SO₃ (%) | 2,2 | ≤4,0 |

| Chloride content Cl (%) | 0,02 | ≤0,10 |

| Ignition loss (%) | 2,0 | ≤5,0 |

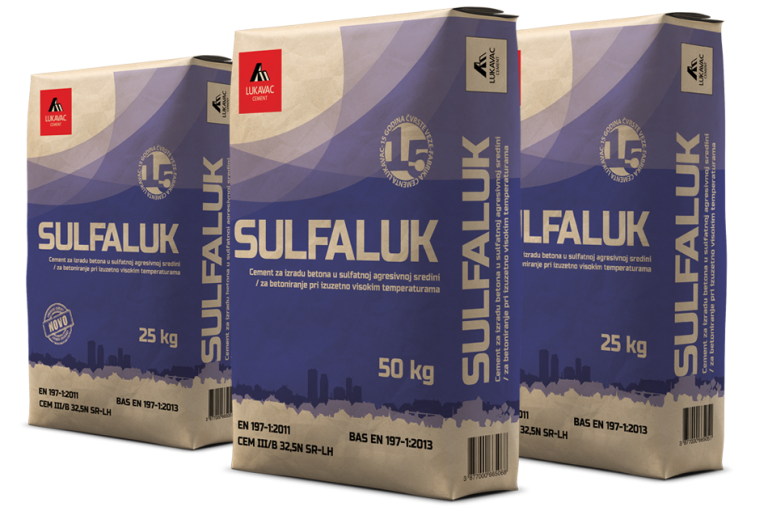

Delivered in bags weighing 25 kg (1.4 t on a pallet) and 50 kg (1.5 t on a pallet).

With proper transport and storage, cement should be used no later than 6 months from the date of production.

Bagged cement should be stored in a dry place protected from atmospheric precipitation, above ground on a pallet or other dry substrate.

Here you can download certificates and press releases made for domestic and foreign markets:

Lukavac Cement d.o.o. is a leading producer of Portland and masonry cement in Bosnia and Herzegovina.

As a member of the Hungarian Talentis Group, we produce different types of cement and own two concrete plants in Sarajevo and Banja Luka, trading company in Zagreb, Republic of Croatia and industrial quarry in Lukavac.

Educated, highly skilled and professional, accountable and, above all, satisfied employees are the foundation of Lukavac Cement business success. Our employees with their skills and knowledge are one of the basic resources of our company and our strongest link in a chain.

Apply for jobLukavac Cement accompanies its customers from the very beginning of the implementation of all complex projects and all the way to construction and building, providing, at the same time, all necessary information on technical details about the cement, counselling about the selection of cement type, optimal use of material, and also the assistance in the process of concrete production and quality control. With highest dedication we do our best to meet all your requirements and ideas related to cement and its use.

You can contact us on free info line:

080 020 601

© 2024 Lukavac Cement d.o.o.