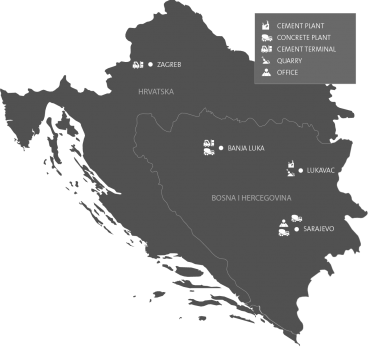

Lukavac Cement started operations back in 1974, and in 2001 Austrian investor successfully conducted the process of privatization. After the construction of completely new preheating line, our annual production capacities started ti reach 700,000 tons of clinker and over 900,000 tons of cement. In 2014 we expanded our operations and introduced a ready mixed concrete as a new segment in production and, in addition, we have started own production in concrete plants in Sarajevo and Banja Luka. The sale of all types of cement for customers from Republic Croatia is carried out through the company “Lukavac Cement HR” Ltd. Sesvete, Zagreb. The factory has 50% ownership over “Vijenac” Limestone Mine, industrial quarry which, apart from Lukavac Cement Plant, supplies other factories in Lukavac with limestone and provides stone aggregates for concrete and lower layers of asphalt. From December 2023, we have become part of the prominent Talentis Group from Hungary.