LUKAVAC CEMENT STARTS THE ROTARY KILN

After stopping the production plants in December 2017, Lukavac Cement Factory stopped producing clinker, but all the activities of the Factory were focused on the overhaul of plants. Employees and Management of Lukavac Cement were pleased to start the first production campaign in 2018 after more than three months of halted production.

Towards the end of 2017 Lukavac Cement completed the third investment phase of the total value of over 25 million KM, which will significantly contribute to the improvement of production efficiency, safety and improvement of existing ecological indicators. Investments were primarily focused on the use of alternative fuels and ecological standards: purchase of the new equipment and upgrade of the alternative fuels dosing system in the part of the heating line for clinker production, and focused on modernization and expenditure of dust bypass and installation of the system for the reduction of nitrogen oxides.

Heating line will utilize the fuel derived from waste processing, so called RDF (Refuse Derived Fuel), and for the use of such fuel, Lukavac Cement Factory has relevant environmental permit from the Federal Ministry of the Environment and Tourism. The Factory also implements prescribed internal procedures for the intake, quality control and use of fuel and therefore it meets all required parameters related to the greenhouse gas emissions required by the regulations of Bosnia and Herzegovina and European Union.

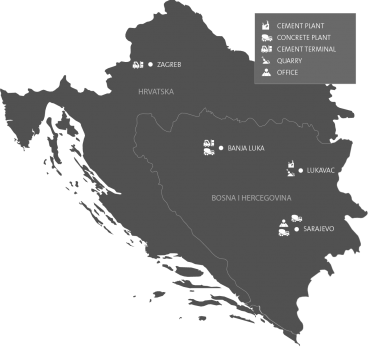

Lukavac Cement Factory is a leader in production of Portland and masonry cement in Bosnia and Herzegovina. Since 2001, the Factory is a member of distinguished business group Asamer from Austria. Because of the innovative approach and investment in modern technology, the Factory was declared in 2008 as the biggest “green field” investment and “Best Foreign Investor” in BiH. With the attitude it has and with its efforts in the field of the protection of the environment, the Factory gained itself a name “Green Cement Factory” and the name is based on certificates ISO 9001:2008 i ISO 14001:2004, in accordance to best European practices and standards.