Cement Plant Lukavac Is Rebranding Business Operations

After expanding business operations on concrete segment, Lukavac Cement Plant decided to split Lukavac Cement Plant trademark on two brands: Lukavac Cement and Lukavac Concrete

It is the proof of the continuous work on modernization and improvement of production, started by the management of the company back in 2001 through successful privatization by ASAMER Austrian Group. Recognizable as the largest domestic producer of cement, the factory enters the segment of concrete production, and as a logical sequence, the need for the construction of a new brand has been created, together with the need for rebranding the existing.

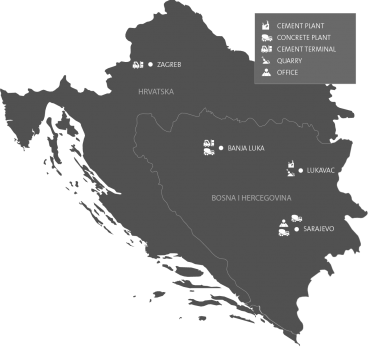

We are a synonym for cement production and by expanding business program on concrete we have decided to take the step forward on the market with two new brands, Lukavac Cement and Lukavac Concrete. In this moment concrete will be produces in our new plants in Sarajevo and Banja Luka, with intention of spreading of the network throughout the whole country in accordance to the demands of the market. We constantly listen to demands of the market, we invent and offer solutions, follow trends in the world and implement best practices, therefore we are quite certain that Lukavac Concrete will become recognizable by its quality, just as Lukavac Cement is”

said Izet Imamović, General Director of Lukavac Cement Plant.