The world, in which the total population approaches figures of 9 billion inhabitants by 2050, has to think in a way that everything that can be used for recycling should be used, and should be utilized in in a good mother’s way for the generations to come. The cement industry could be at the very heart, or at least could be a vital link in the economy, using by-products of other industries.

Austria is a leader in use of alternative fuels in cement industry, with the average fossil fuels substitution rate of 63%. Germany is on the second place, saving 2,3 million tons of coal. Out of 35 cement plants in Germany, 33 use alternative fuels and relevant bodies and services have not recorded adverse effects in last 27 years. Some cement factories have achieved a 100% replacement of fossil fuels with alternative ones. The European average rate of use of alternative energy sources in 2012 amounts to 37%, while the world average is at a lower level with a rate of only 14%. Prospective for the efficient use of alternative fuels will largely depend on the type of the fuel currently available at the market, as well as on the flexibility of some plants to easily switch from one type of the fuel to another, and in large scale it will depend on skills and knowledge of managers in the process of production.

In Bosnia and Herzegovina, the use of alternative fuels in cement industry, but also in industry in general, is still at the beginning. In addition to the fact that utilization of these fuels contribute to an ecologically cleaner environment, companies reduce production costs in because waste is cheaper than fossil fuel. The current legal rate of use of alternative fuels is 30%.

President of Eco Forum Zenica, dr. Samir Lemeš says that waste incineration for the purpose of obtaining energy, if conducted in the proper way, does not harm the environment to the extent that other fuels do.

However, in BiH we do not have enough waste that can be used for this purpose. One plant needs enormous quantity of energy in the process of production and therefore quantities available in BiH can only satisfy a small part of these needs. Also, the non-selective disposal of waste to landfills in BiH is a big problem, because in this way people throw large quantities of usable material”,

said Lemeš.

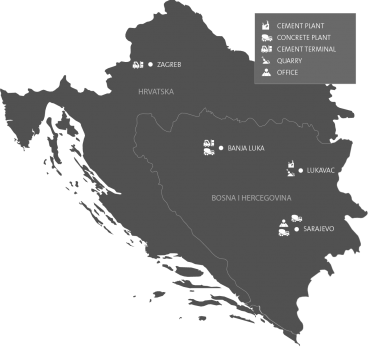

Cement plant Lukavac has kept pace with world trends, and the first in BiH began to use these sources of energy. At present, the share of alternative fuels in their production is up to 30 percent, and the measurements carried out in 2015 showed that the emission of pollutants is below the lowest envisaged values and in accordance with the strict directives of the European Union.